Xuzhou Zhongmei Hitech International Engineering Co., Ltd. Revolutionizes Green Construction with Prefabricated Steel Structure Housing Technology, Leading Industry Transformation

As a leading private innovator in China's construction industrialization sector, Xuzhou Zhongmei Hitech International Engineering Co., Ltd. announced recently that its independently developed "Hantai Low-Rise Steel Frame Prefabricated Housing Technology System" has successfully passed the scientific and technological achievement evaluation by the Ministry of Housing and Urban-Rural Development (MOHURD). This milestone marks the company's strategic upgrade from a single material supplier to a comprehensive green building solution provider in the steel structure construction sector.

I. Technological Breakthrough: Building a Full-Industry-Chain Prefabricated Steel Structure Ecosystem

The newly released technology system, centered on Q355B high-strength steel, integrates three core innovative advantages:

Modular Design: Through parametric modeling, over 85% of building components (walls, floors, roofs) achieve standardized production, reducing the processing cycle for a 200㎡ single-family home to just 72 hours.

Low-Carbon Construction Process: Self-tapping screw connection technology replaces traditional welding, cutting on-site carbon emissions by 60% and construction waste generation by 80%.

Intelligent Operation & Maintenance: Embedded BIM + IoT monitoring systems track the stress status of steel structures in real time, extending service life to over 100 years.

Holding 12 utility model patents and 3 invention patents, this system fills domestic technological gaps in low-rise prefabricated steel housing, particularly in seismic performance (withstanding 8-degree seismic intensity) and thermal efficiency (wall heat transfer coefficient ≤ 0.35W/㎡·K).

II. Market Implementation: First Affordable Housing Project Achieves "Year-Round Design-to-Delivery"

Leveraging this technology, Xuzhou Zhongmei Hitech’s 30,000 m² prefabricated steel structure affordable housing project in Xuzhou’s Jiawang District topped out last month. Adopting a "factory prefabrication + on-site assembly" model, the construction cycle was shortened by 40% compared to traditional brick-concrete structures, saving 35% in labor costs. Third-party testing shows indoor formaldehyde levels as low as 0.02mg/m³ (national standard: 0.08mg/m³) and sound insulation reaching 45dB, fully meeting China’s three-star green building standards.

III. Private Enterprise Innovation Path: Transition from "Manufacturing" to "Smart Manufacturing"

The company’s technological breakthrough stems from three strategic initiatives:Scenario-Based R&D: Targeting rural revitalization and cultural tourism real estate, it has developed differentiated housing types with sloped roofs and large spans, forming 6 major series and 32 standardized floor plans.

Lightweight Supply Chain: Partnering with 12 steel processing enterprises within 50km, it reduced component transportation costs by 25% and compressed emergency order response time to 24 hours.

Policy Dividend Utilization: Actively responding to MOHURD’s "14th Five-Year Plan" for prefabricated buildings, it participated in formulating 3 provincial technical specifications for steel structure housing, emerging as an industry standard-setter.

IV. Industry Impact: Opening a New Chapter for Market-Oriented Steel Structure Housing

With China’s "Double Carbon" goals driving progress, the prefabricated building market is expected to reach RMB 3.6 trillion by 2025, with steel structures accounting for 30% of the market. Xuzhou Zhongmei Hitech’s technology is projected to reduce the construction cost of steel structure housing by 15%-20%, promoting its transition from government-subsidized affordable housing to commercial real estate. The company plans to build 3 intelligent production bases in Jiangsu and Shandong provinces by 2024, achieving an annual production capacity of 500,000 m² to support the "Thousand Cities, Ten Thousand Villages" green building transformation initiative.

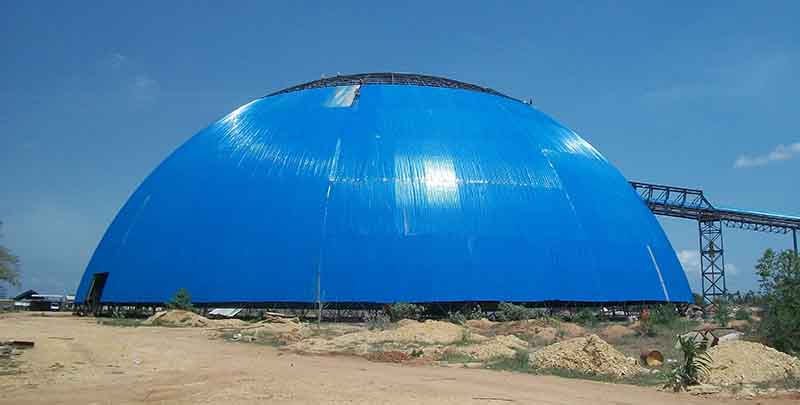

This achievement not only demonstrates the innovative resilience of private enterprises in niche sectors but also marks a historic shift of steel structure buildings from "industrial factory use" to "mainstream livable architecture." Xuzhou Zhongmei Hitech will focus on technology system output, collaborating with upstream and downstream enterprises to build a steel structure construction industrial community and contribute to China’s carbon neutrality goals.